Designing a ship that will be used under some of the most strenuous circumstances is a big responsibility. That’s why you need to use metal maritime filters that perform better under corrosive conditions than legacy filter elements.

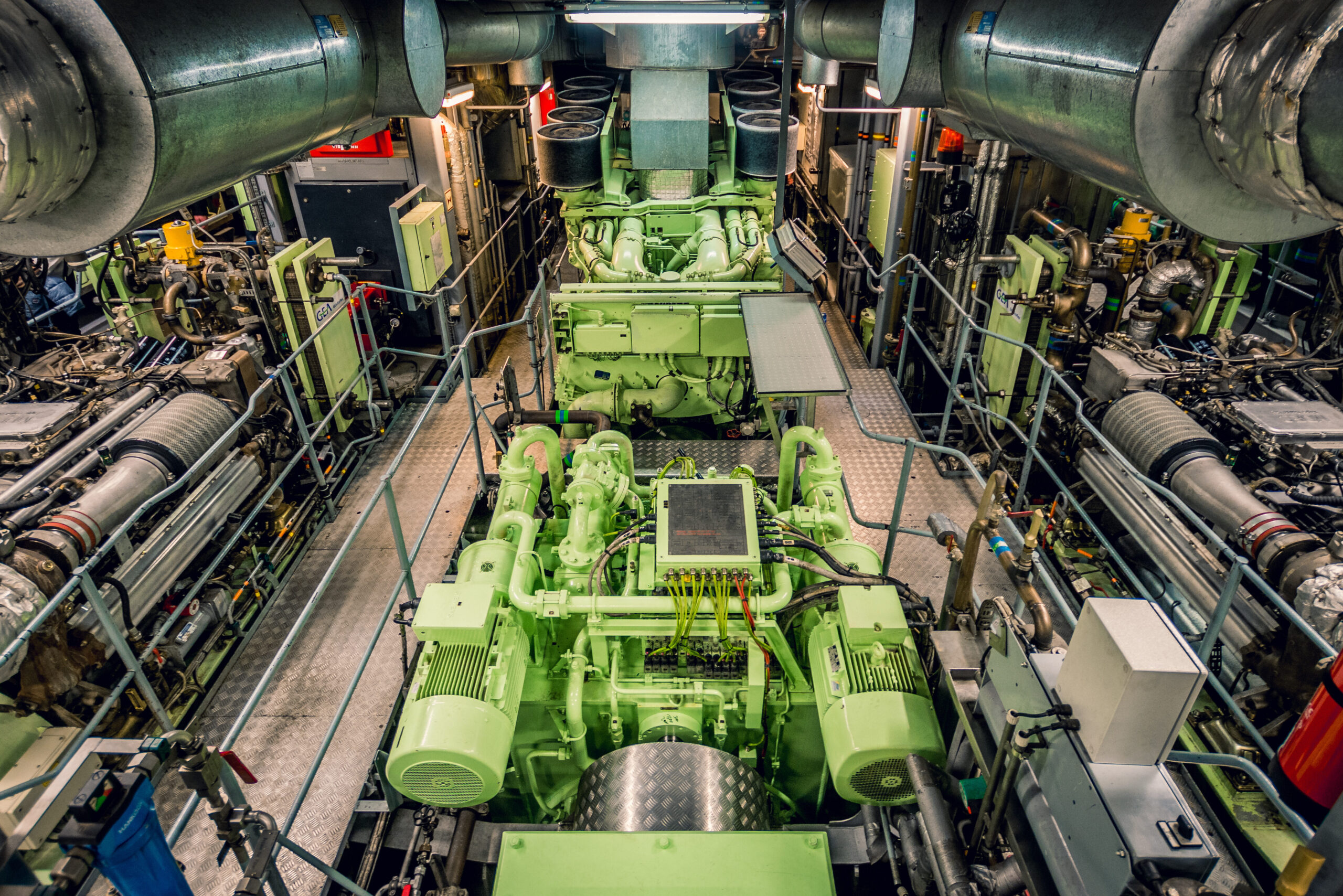

When you design or manufacture a ship’s systems, its performance is only as good as its engine. The problem is that maritime filters often come in contact with corrosive salt water, sludge, and other contaminants that threaten their efficiency and put the entire ship’s operation and crew in danger.

You’ve worked hard to design and build a ship that can meet the high demands of the U.S. military. Give it the best all-metal filters and filter housings to protect your motor, turbines, indoor air, hydraulic system, and more.

Need Custom Marine Fuel Filter Housing?

Your fuel system is only as good as your filter because if harmful contaminants reach the engine, they decrease its efficiency and lifespan. Better protect your ship’s engine with a myriad of marine inline fuel filters, housings, and specialized enclosures to meet your needs and specifications.

Can the Navy Rely on Your Propulsion, Handling, and Maneuvering Systems?

Hydraulic systems need durable maritime filters that operate efficiently and are a safe choice for all marine applications. Our comprehensive range of hydraulic filtration units will meet those needs.

Want Protection From Corrosive Seawater?

Keep your vessel operating even in the most demanding conditions! Get robust and reliable marine water filtration and separation equipment with the tried and tested designs you can count on for clean and safe water availability.

Need a More Robust Air Filtration Solution?

Some of the biggest Naval vessels in the world have utilized our air filters and screens, such as the US Navy DDG 51 destroyers. These customized air filters and screens come in various designs and material options. Just let us know what you need!

No matter what your filtration needs, Fluid Conditioning Products can help! Our team has spent decades researching, developing, refining, and manufacturing the best metal filters on the market. Take advantage of these years of experience and knowledge by ordering a custom maritime filter today!

When the best of the best chooses a company as their preferred supplier, that supplier must have an exceptional product. So when you learn that companies such as the U.S. Navy, General Dynamics Electric Boat, and General Electric prefer our marine inline fuel filters, hydraulic system filers, and water and air filters, you know that our product is the best. See why these top companies choose Fluid Conditioning Products!

Huntington Ingalls, Newport News Shipbuilding ensures the U.S. Navy’s maritime dominance by providing the surface Navy with a wide range of marine capabilities. These resources include ships, aircraft, manned and unmanned systems, projectiles, and sensors. They depend on us to provide them with the maritime filters they need to provide efficient filtration solutions for the safe operation of their motors and turbines.

General Electric’s global marine business offers customers the latest advances in gas turbines, diesel engines, electric drives, and dynamic positioning solutions to support global growth in the marine industry. But these engines wouldn’t be as powerful if their maritime filter shed particles that contaminate the downstream processes. That’s why they use our all-metal, corrosion-resistant wire mesh filters, which reduce contaminants by about 95%!

General Dynamics Electric Boat designs and builds submarines. With over a century of experience, the U.S. Navy depends on this company to develop and integrate complex systems for each of its unique naval ships. And that’s why General Dynamics Electric Boat depends on us! They know that our various maritime filters can provide unbeatable filtration quality needed for these warships.

Ship manufacturers want their vessels to operate efficiently with little downtime for repairs. So, they need an experienced manufacturer of marine inline fuel filters, fuel water separators, and so much more. The problem is that most filter manufacturers use legacy materials, such as paper and fiberglass, to make their products.

These materials cause more damage to the engines than help, as microscopic particles break off during the intense conditions they endure, such as high heat, corrosive environments, and intense movement. These particles lead to more repairs needed on the engine and other downstream components, which can mean the difference between life and death.

We believe all-metal filters, made from stainless steel, nickel-copper, brass, and bronze, are the better choice. And studies back that up too! Baekert published a white paper that details how metal fiber filters reduce maintenance by 10 times on six components versus fiberglass!

Your vessel also deserves that level of filtration, which is why we have been the leader in manufacturing metal filters for over 60 years. Here’s how we do it:

After you tell us what you need to filter and the quality specifications, we get to work drawing up a proposal. We determine product specifications in more detail when approved, create drawings, and obtain any machinery or tools.

Based on the plans you approved, we create a prototype. We present this initial prototype to you to see if it meets your standards. If not, we go back to step one until the prototype meets the necessary quality standard.

When the preparation is complete, we will start manufacturing your maritime filter and any necessary finishes. We then inspect each item carefully, process them for shipment, and deliver the final product to you.

So please request a quote today from our friendly customer service team! And in the meantime, check out valuable information on our blog to learn more about how to get the superior marine filtration you deserve.

Whether you need to meet specific requirements, such as a filtration system that requires reverse flow prevention, or are looking for something more standard to filter out contaminants, we can help! We can design filters to your specification, including ones with proper check valves to meet your conditions.

We’ve set standards for performance and dependability in manufacturing metal filters for over 60 years. The products we make are essential in designing and operating next-gen propulsion technologies. No matter your filter design requirements, get in touch with us today for a quote! We’ll be happy to help you design and build a more efficient and long-lasting vessel.