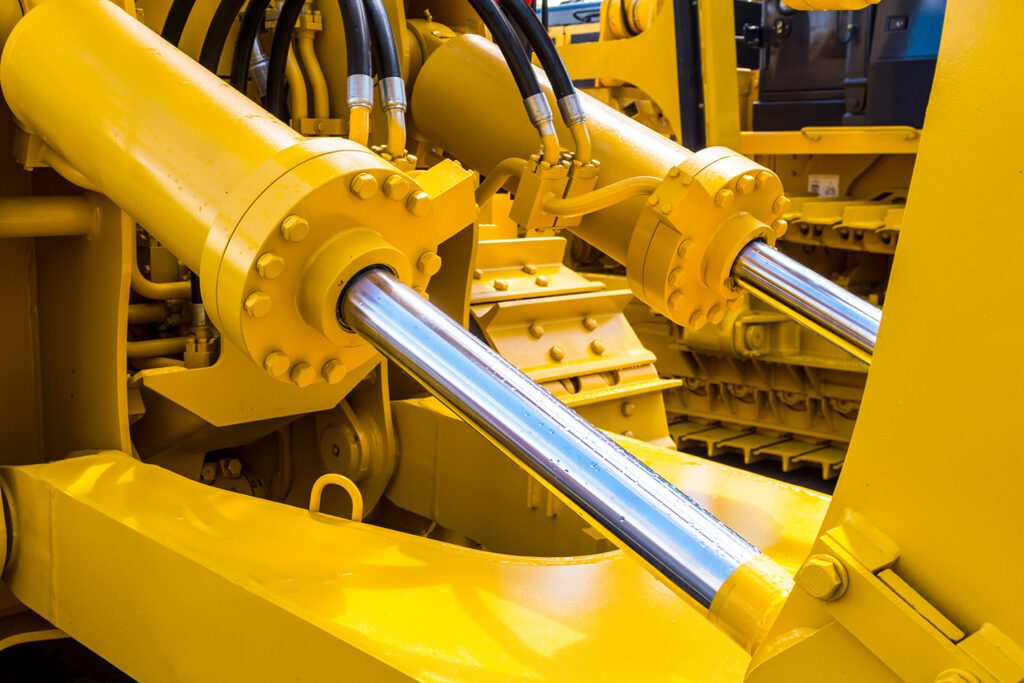

Hydraulic systems are among the key components of modern machinery. From construction equipment to manufacturing machinery, these systems perform critical work, often under intense pressure. Yet, the single most common cause of hydraulic system failure is contamination in the hydraulic fluid. This is where hydraulic fluid filters come into play. These essential components protect your investment, optimize performance, and dramatically extend the life of your equipment.

Why Does Clean Hydraulic Fluid Matter?

When you think about what keeps a hydraulic system running, the first thing that might come to mind is hydraulic oil. But having an effective hydraulic system is not just about having fluid, it’s about keeping it clean. Hydraulic fluid acts as the lifeblood of a hydraulic system. It powers the movement of pistons, actuates controls, and ensures everything functions smoothly. However, this fluid is also vulnerable to contamination from metal particles, dust, water, and degraded oil.

Contaminated hydraulic fluid is abrasive and corrosive. Over time, it can damage seals, clog valves, erode pumps, and cause entire systems to stop. This results in costly downtime, expensive repairs, and shortened equipment lifespan. Proper hydraulic filtration is the most effective line of defense against these threats.

How Hydraulic Fluid Filters Work

Hydraulic fluid filters work by capturing and removing harmful particles from the oil before they damage your equipment. You’ll find these filters placed throughout the system—in suction lines, pressure lines, return lines, and offline filtration loops. Each one helps maintain cleaner fluid and protects your machinery from unexpected issues.

There are different types of hydraulic filters, each designed for specific applications:

- Return filters clean the fluid as it returns to the reservoir.

- Suction filters prevent contaminants from entering the pump.

- Pressure filters protect downstream components by filtering fluid under pressure.

- Offline filters work in a separate loop to continuously filter fluid, even when the system is idle.

Each filter is rated by its micron rating, which indicates the size of particles it can remove. High-performance systems often require filters that capture particles as small as 5 microns.

Hydraulic Systems and the Cost of Contamination

A single teaspoon of dirt in a 55-gallon drum of hydraulic fluid may seem insignificant, but it can cause significant damage to a sensitive system. Industry studies show that up to 80% of all hydraulic failures are related to fluid contamination. These failures can include:

- Pump wear and cavitation from solid particles

- Valve sticking due to sludge and varnish buildup

- Seal degradation caused by chemical contaminants

- Heat generation from increased friction and inefficient fluid flow

Once contaminants begin to circulate, the damage becomes exponential. That’s why filtration is a necessary step in maintenance.

The Role of Oil Filters in Preventive Maintenance

If you’re committed to keeping your equipment in top shape, the right tools matter. Hydraulic oil filters play a key role in preventing problems before they start. By staying on top of filter replacements, you reduce the risk of surprise breakdowns and keep your operation running smoothly.

Preventive maintenance that includes frequent filter inspection and replacement brings several benefits:

- Lower operating costs by avoiding catastrophic failures

- Higher efficiency from clean fluid and reduced resistance

- Longer system life due to reduced component wear

- Improved safety through reliable machine performance

Keeping a stock of the correct filters and adhering to a maintenance schedule tailored to the system’s usage patterns can make all the difference.

Choosing the Right Hydraulic Filtration System

Not all hydraulic filtration systems are created equal. Choosing the right filter depends on several factors:

- System pressure and flow rate

- Operating environment (clean room, outdoor, heavy dust, etc.)

- Contaminant types and expected load

- Fluid type and viscosity

- Component sensitivity

Advanced filtration systems may include pressure indicators that signal when a filter needs to be changed, or bypass valves that allow flow to continue if the filter becomes clogged. Modern options even offer condition monitoring, providing real-time updates on fluid cleanliness and filter status.

Proper sizing and placement of your filters, based on system specs and performance goals, ensure you get the full benefits of hydraulic filtration without restricting flow or overburdening the system.

Hydraulic Fluid Filters and Equipment Longevity

Clean hydraulic fluid helps prevent failure and actively enhances performance. Equipment runs smoother, responds faster, and requires fewer repairs when the hydraulic fluid is kept free from contaminants. Hydraulic fluid filters are the unsung heroes that make this possible.

Partner with Fluid Conditioning Products for Premium Hydraulic Fluid Filters

To keep your hydraulic systems performing at their best, fluid cleanliness should be a top priority. That’s where hydraulic fluid filters make a difference. At Fluid Conditioning Products, you’ll find filtration solutions designed to match your military equipment’s specific needs.

Whether you need hydraulic fluid filters for replacements or complete systems, we’re here to support your goals. Reach out today to design the right filter for you that can reduce downtime and help protect your equipment.